Again the starting alcohol results from a multi step process adding to the cost of the whole process and decreasing the overall yield.

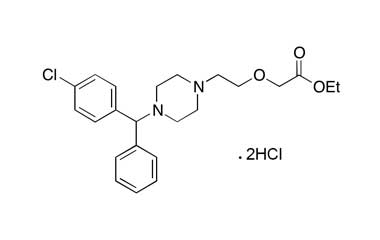

Again as all the starting materials are not commercially available and it results in a multi step process which generally is costly.Ĭanadian Patent 1,320,732 relates to a process for preparing cetirizine by reacting -1-piperazinyl]-ethanol with an alkali metal haloacetate. Immunol., 80, 80, 599 (1987).Ĭanadian Patent 1.199,918 describes the synthesis of cetirizine following two different routes as illustrated in Scheme 1: #STR2#Īll the starting materials require for these 2 routes are not commercially available and accordingly these two routes involve a multi step process resulting in low overall yields.Ĭanadian Patent 1,317,300 teaches a process for preparing cetirizine by reaction of 1-[(4-chlorophenyl)phenylmethyl-piperazine with an haloethoxyacetonitrile. It's pharmacological and medicinal properties have been described in the literature, C. 1-piperazinyl]ethoxy]acetic acid also known by the generic name of cetirizine is a non-sedating type histamine H1-receptor antagonist and is used in the treatment of allergic syndromes. The term "lower alkoxy" as used herein means residues of both straight and branched chain aliphatic alcohols having from 1 to 4 carbon atoms, such as methoxy, ethoxy, butoxy and the like. #STR1# where R 1 and R 2 represent independently a hydrogen atom, a halogen atom, a lower alkoxy radical or a trifluoromethyl radical.

The present invention relates to a new process for the manufacture of -1-piperazinyl]ethoxy]acetic acid derivatives of formula I and in particular for the manufacture of cetirizine.

0 kommentar(er)

0 kommentar(er)